BLOG

From Isolation to Insight: Building Safer

Remote Worksites with SmartOps

NOVEMBER 15, 2025

CATEGORY: CONNECTED WORKER SOLUTIONS

The Growing Challenge of Remote Worksites

Whether it’s a construction site in a remote desert, a mining operation deep underground, or an oil rig miles off the coast, working in isolated locations presents a unique set of risks. When workers are far from help, poor communication, delayed decision-making, and lack of supervision can turn small issues into catastrophic events.

How do you ensure safety when your workforce is spread out over vast, inaccessible areas? The answer: connected worker solutions.

Why Traditional Safety Measures Don’t Work in Remote Environments

In conventional work environments, safety officers can oversee operations in real-time, managing risks and responding quickly when things go wrong. But in isolated locations, traditional safety management falls short.

- Limited Visibility: Supervisors often don’t have a clear view of remote worksites.

- Delayed Decision-Making: Without live monitoring, every incident is a race against time.

- Compliance Gaps: Manual check-ins and reporting leave too much room for errors and non-compliance.

These gaps contribute to a higher risk of accidents, delayed rescues, and unchecked violations.

The SmartOps Solution: Real-Time Safety and Monitoring

Jarsh’s SmartOps ecosystem is built to overcome the challenges of remote worksites by integrating IoT-enabled wearables, connected cameras, AI-powered audits, and real-time alerts.

SmartOps provides 100% visibility, even if your site is hundreds of kilometers away, making it possible for safety officers to remotely monitor operations, ensure compliance, and respond immediately to any potential hazards.

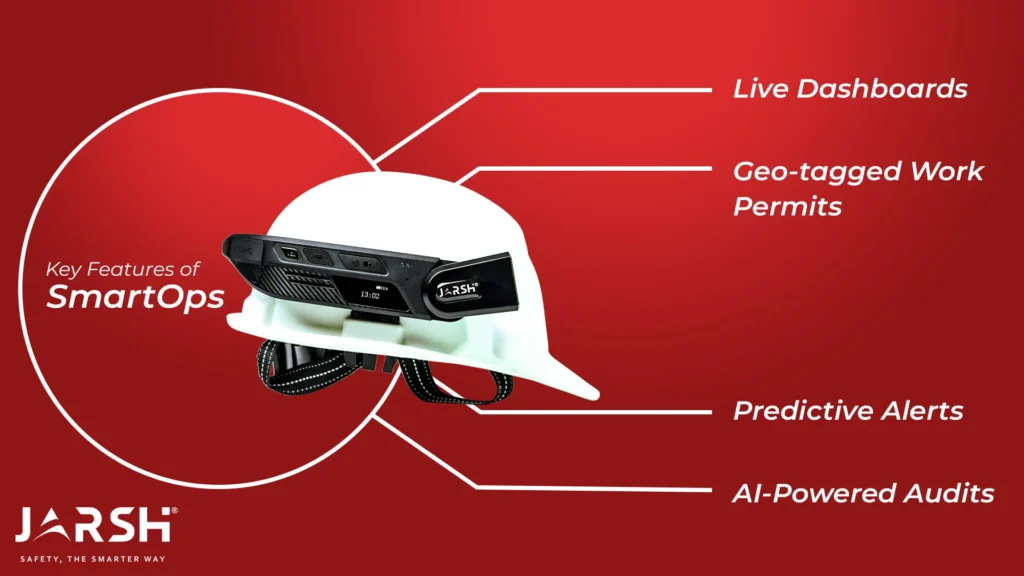

Key Features of SmartOps:

- Live Dashboards: Track worker location, health metrics, and equipment status in real time.

- Geo-tagged Work Permits: Digitally log and verify work permits, ensuring proper safety checks before any task begins.

- Predictive Alerts: Get automated alerts for equipment malfunctions, safety breaches, or hazards before they escalate.

- AI-Powered Audits: Leverage artificial intelligence to cross-check worker actions against safety protocols.

SmartOps turns remote work sites from isolated zones into fully connected, self-regulating environments.

How WorkAlive™ Takes It a Step Further

For industries that face confined spaces or hazardous conditions, such as mining, chemicals, or oil & gas, WorkAlive™ — a portable camera system — enhances SmartOps by providing live video streaming of the worksite in real-time.

- Real-Time Monitoring: Supervisors can remotely view operations on-site, ensuring safety protocols are followed.

- Instant Communication: Workers can send live images or videos to supervisors for immediate feedback or approval.

- Safety Alerts: In the event of an emergency, WorkAlive™ instantly connects workers to remote teams, ensuring quick responses.

The Results: Reduced Risks, Increased Efficiency

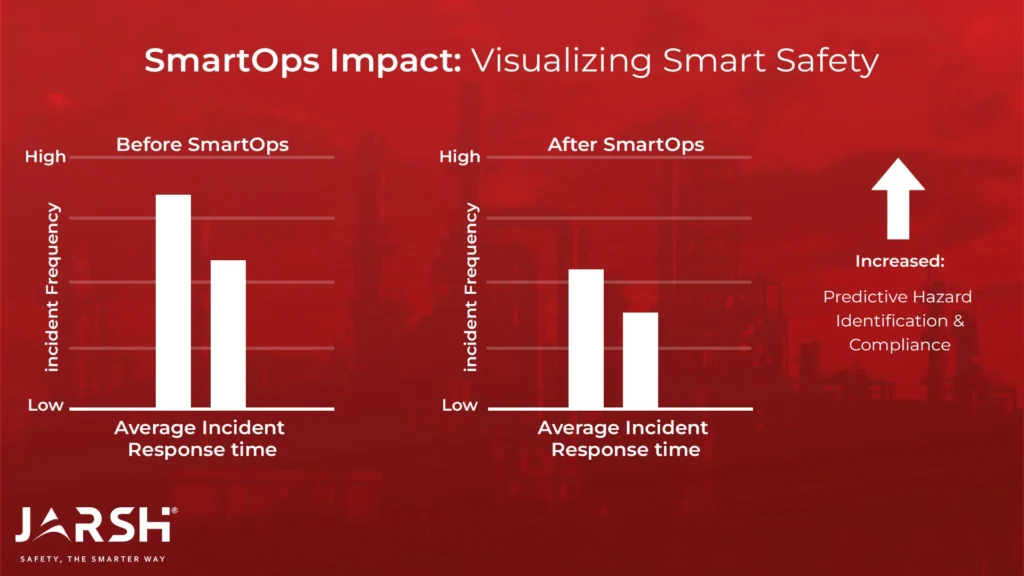

When companies implement connected worker solutions like SmartOps, they aren’t just improving safety – they’re boosting productivity too.

- Faster Incident Response: With live alerts and video monitoring, issues are addressed before they become critical.

- Improved Worker Morale: Workers feel safer knowing they’re continuously monitored and that help is just a click away.

- Compliance and Accountability: Automated systems and real-time data ensure safety standards are met and audited correctly.

Why SmartOps Is the Future of Remote Worksite Safety s

As industries evolve, so do the risks and challenges of operating in isolated areas. To stay ahead, companies must invest in intelligent safety systems that not only react to hazards but anticipate them. SmartOps is more than just a safety tool — it’s an ecosystem that enables companies to predict, prevent, and protect their workers, even in the most remote and dangerous environments.